Put Some Spark in that Muzzleloader

By Glen Wunderlich

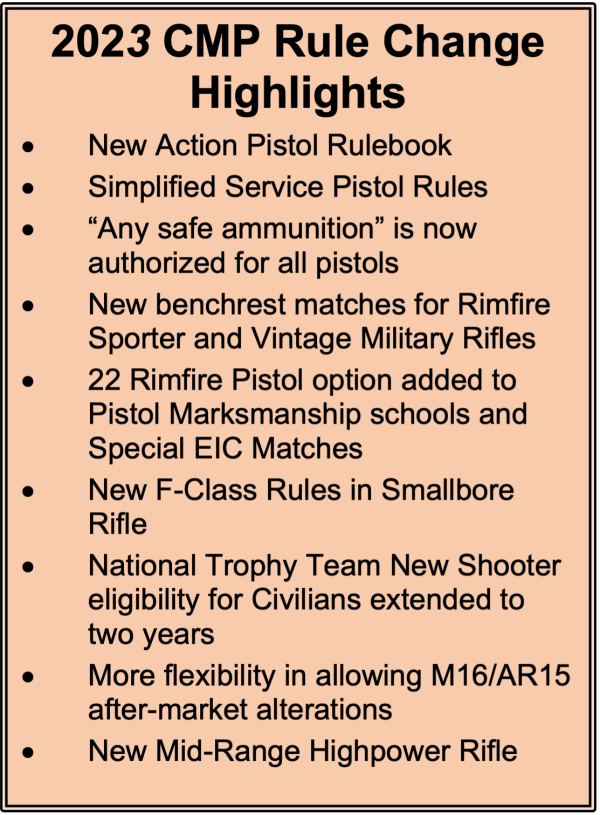

Since my old reliable Knight Revolution muzzleloader never needed much tweaking to be ready for the season opener, waiting until the last week didn’t seem problematic. On hand were a supply of Barnes bullets and fresh Triple 7 powder and primers from last season, which were stored in a sealed plastic bag. An upgrade in power with a new Leupold scope meant there’d be some sighting in. But, that would be the case anyway – new scope or not.

Boresighting had the first shot on the paper, but with more shooting came less confidence. Shots were all over the place and then it got worse: A misfire!

After a “good” cleaning and another five shots, another misfire. My cleaning procedure included blowing out the breech plug’s flash channel and flash hole with aerosol Gun Scrubber. My only test would be to look through the tiny hole for light. Until now, this critical ignition link had not been a suspect in the malfunctioning dilemma.

But, then I recalled how an older model muzzleloader gave me similar troubles – and, sometimes even dangerous hangfires. I say dangerous because any shooter must know to keep the muzzle pointed toward the intended target, if your gun doesn’t fire immediately and not begin to do anything else for a half minute.

When it occurred in the field on one occasion, I was able to make a perfect shot with proper follow through – much like is done routinely with flintlocks. You must be mentally prepared for such an occurrence.

In any case, a new breech plug was all that was needed.

Naturally, I once again looked to replace the ignition glitch by getting a new breech plug for the current smokepole. But it was no dice. Obsolete. Discontinued.

Fortunately, a friend with better eyesight than mine noticed that the flash channel appeared dirty. Since I had a set of torch tip cleaners (or orifice cleaners), a larger one was pushed back and forth through the larger flash channel. Then, the tiny flash hole was cleaned with smaller cleaning wire. There was an obvious difference. The crucial ignition opening was never cleaned properly, and most likely that’s all that was ever wrong with the previous muzzleloader.

The CCI 209M shotshell primers being used were filthy and causing all the headaches. Even though they were used last season, the buildup in the breech plug orifice wasn’t extensive enough for malfunctions.

Back at the range, it didn’t take long to dial in the frontloader. And, this time groups were consistent. A switch to Remington’s Kleanbore muzzleloader primers showed a remarkable difference upon removal and inspection of the heretofore problematic breech plug.

The lesson is that normal use will cause primer-fouling buildup and it takes the proper tools to remove the crud. Brushes, picks and pipe cleaners won’t do it. Determine the proper size drill bits for the two-step hole – one for the flash channel and one for the flash hole and turn them by hand. Do not remove any metal in the process.

Just follow these simple steps for more reliable ignition and you can avoid one of the pitfalls of modern muzzleloaders.