Krytos Industries Launches Titanium Finish and Titanium Glock Slides

Akron, OH –– Krytos Industries launched a revolutionary titanium finishing process along with titanium slides for Glock handguns at the 2018 NRA Convention in Dallas, Texas on May 4th. The new, patented finishing process, ArmorTiTM, allows titanium to be used for numerous applications (like handgun slides and frames) that were not previously possible as it eliminates galling and other friction and impact related issues inherent to titanium.

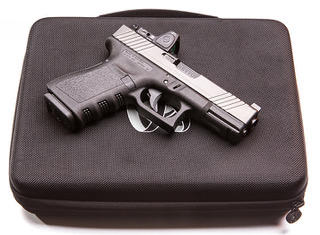

Through extensive testing with ArmorTiTM treated titanium components, Krytos has shown that many handgun slides can be replaced with one made completely of titanium to reduce the overall weight of the handgun by 25% or more while maintaining its performance. With titanium weighing roughly 45% less than steel, the felt weight reduction is dramatic. For example, a factory Glock 19 (Gen 3) slide weighs 11.5 ounces while Krytos’s G19 slide weighs in at a mere 6.4 ounces. Further, all participants involved in testing reported that the increase in felt recoil was negligible, but did state that sight recovery on target was dramatically faster (this was attributed to increased slide velocity and reduced slide mass resulting in less “muzzle dip” upon returning to battery). The company’s first products to market, shipping now, are handgun slides for the Glock 17 and 19 (both offered with optional cuts for the Trijicon RMR®), titanium guide rods for the Glock 17 and 19, and bolt carriers for the AR-15 (.223/.556) and AR-10 (.308). All of Krytos’s titanium products are precision machined to exacting tolerances from solid billets of 6AL-4V, Grade 5 titanium and finished with their exclusive ArmorTiTM process for an extremely hard, black finish.

“This is an exciting time for our young company,” said the company’s President, Ben Cook. “We were overwhelmed by the reactions we received from attendees and our industry partners at the NRA Convention this year. ArmorTiTM has consistently amazed us with what it allows titanium to do and we truly believe it will change the face of material design considerations in the firearms industry and many others. ArmorTiTM was designed with aerospace and medical applications in mind, but since we are all firearms industry veterans, we couldn’t help but launch in this industry first. Using our team’s considerable industry experience, we have tested our products to extreme levels to ensure they live up to our standards, which are ridiculous.”

ArmorTiTM is a state-of-the-art process that involves a precisely-controlled, forced diffusion to harden titanium’s surface that results in a black finish with unparalleled durability, far surpassing anodizing and even PVD/DLC finishes on titanium. Through a diffusion process, ArmorTiTM only affects the surface layer of the titanium leaving its integrity and all of the most desirable properties of titanium intact at its core. ArmorTiTM allows titanium to now be used for applications it was not previously suited for due to titanium’s tendency to gall (a form of wear caused by friction welding between sliding surfaces) when sliding against another surface. ArmorTiTM completely eliminates any friction-related issues with titanium and dramatically improves titanium’s impact resistance while maintaining all of its most desirable properties. While the process itself is extremely different, aesthetically, ArmorTiTM produces a familiar black finish like those found on most modern polymer handgun slides.

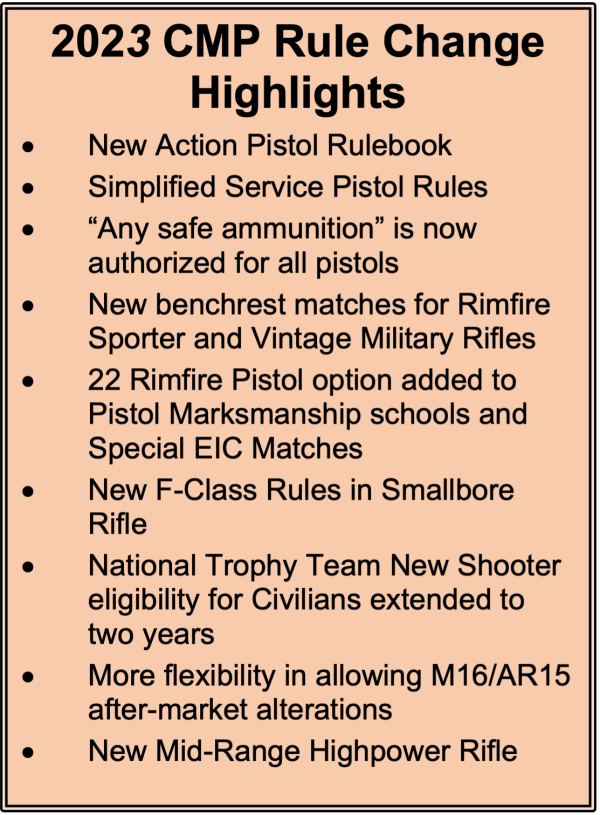

Krytos’s titanium products available now are:

Glock 19 Ti Slide – $549.99

Glock 19 Ti Slide w/RMR cut – $599.99

Glock 19 Ti Guide Rod – $59.99

Glock 17 Ti Slide – $549.00

Glock 17 Ti Slide w/RMR cut – $599.99

Glock 17 Ti Guide Rod – $59.99

AR-15 Ti Bolt Carrier (5.56/.223) – $369.99

AR-10 Ti Bolt Carrier (.308) – $429.99

For more information about Krytos Industries and ArmorTi or to purchase products please visit www.KrytosIndustries.com.

About Krytos Industries

Krytos Industries is a provider of advanced titanium heat treatment finishing solutions and precision titanium components for the firearms, aerospace, medical, and outdoor markets. Krytos’s patented titanium finish, ArmorTiTM, is an advanced, temperature-controlled diffusion process that optimizes the heat treatment of titanium alloys used in applications producing high-friction and impact. ArmorTi’s patented process allows titanium to be utilized in applications not possible with untreated titanium and dramatically outperforms other finishes currently available for titanium while providing an aesthetically pleasing black finish. In the firearms industry, Krytos offers a number of aftermarket components, like handgun slides and AR-15 bolt carriers, that dramatically reduce a firearm’s weight while maintaining or improving its overall performance.