Trulock Choke Tubes Shares How to Pattern Choke Tubes for Turkey Hunting

Whigham, GA (April 28, 2022) – Leave it to the choke tube specialists at Trulock® Choke Tubes providing simple steps to patterning shotguns for turkey hunting. The key, according to George Trulock, president of Trulock® Choke Tubes, is to have a very dense core with as many pellets as possible inside of a 10-inch circle. Plus, George recommends doing this from sitting and kneeling positions to better mimic a turkey hunting experience.

When is it time to pattern a shotgun? George Trulock responds, “You should pattern a shotgun when it is new to you, when you are using a different brand of ammo, or load, or size shot, and especially when using a different choke tube – even if it has the same exit diameter as a previously patterned choke.”

To pattern a shotgun for turkey hunting, the following are needed: several sheets of poster board of at least 3-4 feet wide; marking pen, up to five identical shot shells; tape measure to measure the distance from the shotgun muzzle to the target and a target stand to attach your poster board.

Next steps:

1. Measure 40 yards from the shooting position to the target, which is the most typical length for turkey hunting.

2. Carefully aim the shotgun at the center of the target; keep the bead on the aiming point and squeeze the trigger.

3. Repeat this five times using a different target for each shot.

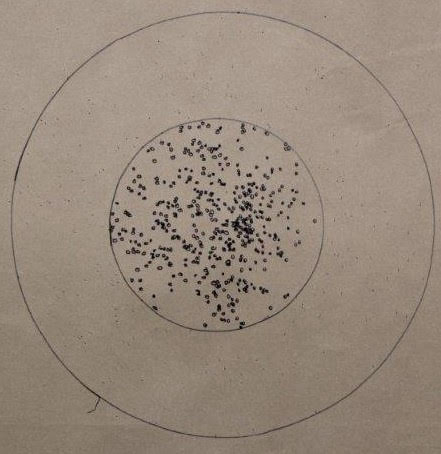

4. Carefully examine each target to visually locate the center point of the densest portion of pellet strikes and mark that spot. Draw a 10-inch diameter circle centered on the previously made location mark.

5. Count the number of hits inside of the 10-inch circle on each target.

6. Add the numbers from each target and divide by five.

7. This number will be the average pellet count in the 10-inch circle for each of the five shots

George Trulock shares that turkey hunters can go a step further to know the percentage of the pellets in the 10-inch circle.

Take out five additional shells that are the same as the ones used for patterning.

1. Cut the ends, remove all the shot, and put them all into a container.

2. Count all the shot and divide by five.

3. This gives the average number of pellets in each shell.

4. Divide the average number of hits in the 10-inch circle discovered earlier by the average number of shot in each shell.

5. The number obtained will be the percentage of shot in the 10-inch circle.

“Shooting one or two patterns is better than not patterning at all, but you will get shot counts that are much closer to a true average by shooting a minimum of five times. More is always better,” stated George Trulock.

All Trulock® Chokes are backed with a 60-day satisfaction guarantee and a lifetime warranty. Check out TrulockChokes.Com for choke recommendations with lead or steel shot, for a variety of game. Contact us at TrulockChokes.Com, or if you want to talk to a real live person and get the absolute best in customer service, then reach out at 800-293-9402. At Trulock® Chokes, customer service is not just a name; it is something the company is dedicated to giving.

Trulock® Choke Tubes: Constriction specialists that enhance a shooter’s natural ability. Explore the many options of choke tubes to fit most shotguns at trulockchokes.com. Follow Trulock on Facebook at https://www.facebook.com/trulockchoke, on Instagram athttps://www.instagram.com/trulockchokes/, Twitter https://twitter.com/trulockchokes, and LinkedIN athttps://www.linkedin.com/company/trulock-chokes

About Trulock Choke Tubes

George Trulock began manufacturing chokes in 1981 to solve the dilemma of creating a choke system that could be retrofitted into most shotgun barrels without the use of an adaptor or machine tools. His final design launched The Tru-Choke™ style choke tube in 1982. Since then, this proprietary system has been adopted by several shotgun manufacturers as O.E.M. and copied by a number of aftermarket choke makers. Trulock Chokes now stocks approximately 2,000 different choke part numbers and has come a long way from George’s first piece of production equipment, a Warner and Swasey # 2 turret lathe.

Trulock Chokes has grown from a one-man show to a company that employs 30 people producing products 24 hours a day, 5 days per week. Trulock® Choke Tubes is still a family-owned business with George’s sons, Scott and Jerrod, a vital part of the management team.

Trulock Chokes has three goals: to make the best product, to give the best customer service and to have 100 percent customer satisfaction. In the event a customer is not completely satisfied with their purchase, they can return it for a refund or exchange within 60 days from the date of purchase. Watch videos and get questions answered on what type of choke to buy at https://www.youtube.com/user/TrulockChokes. Buy TrulockÒ Chokes online at TrulockChokes.Com.