New Clothes for the Ruger American

By Glen Wunderlich

Charter Member Professional Outdoor Media Association (POMA)

At long last my newly suppressed Ruger American rifle in .450 Bushmaster had shown good promise in the initial testing for accuracy. The chosen ammunition had produced a more-than-respectable test group with the new muffler, but it still needed to be sighted in at 100 yards. Since this same ammo had been tested for integrity and accuracy in seasons past, all that was remaining was to adjust the zero. That was a week ago, but things are different now.

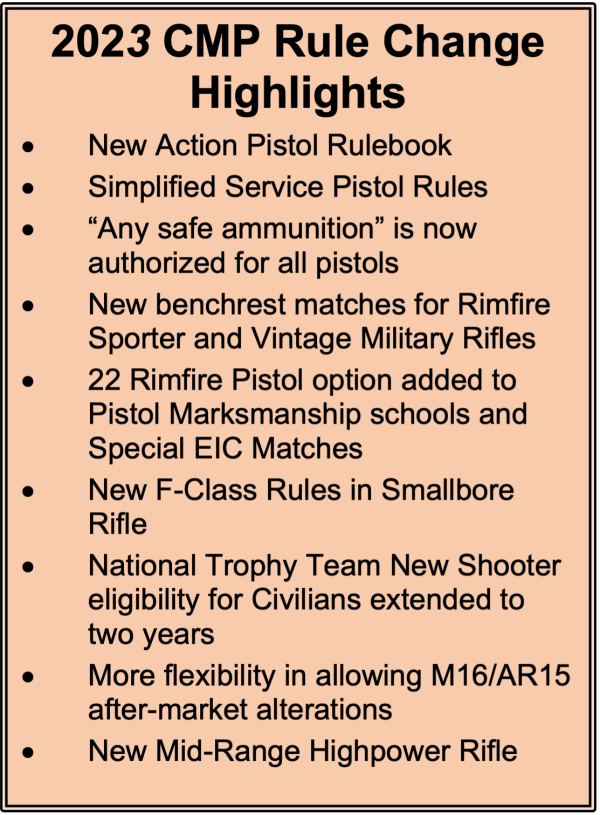

I’ve been meaning to separate the barreled-action from the cheap factory, synthetic stock. Although it was not technically “broken” there was no better time to fix rather sharp edges paralleling the barrel the entire length of the forearm. With the stock in a suitable vise it was shaved and sanded. Ah, that’s better.

However utilitarian, though, that stock was still plain ugly and thoughts turned to a cosmetic upgrade. With some hydrodipping on the menu, I returned from the local Cheap Mart with four cans of quality Rust-Oleum 2X spray: green, brown, copper metallic and clear. The simple process involved filling a plastic-sheet-lined wheelbarrow with water then spraying the surface in educated randomness and dipping the boring stock through the controlled concoction.

However, when I hung it to dry, bubbles formed in my Picasso and the paint had runs – possibly from too much paint in the mix. With nothing to lose, I impatiently began sanding, as soon as it was dry enough. After finishing with ooo steel wool, it was saved and will only need clear coats to become a one-off original.

The Ruger American Dressed Up

Never settling for “good enough”, I began sniffing around the ammo department of www.MidwayUSA.com and couldn’t believe Barnes legendary copper Triple Shock X (TSX) ammunition was available for $40 per box. I gobbled up a couple.

My go-to ammo – Federal Fusion 260-grain ammo – is some tough stuff and beat everything offered by Hornady in my head-to-head testing for integrity. However, it did lose some weight.

Barnes, on the other hand, is even tougher. It is designed for rapid expansion, high weight retention, and deep penetration. When they say “high weight retention”, how about 100 percent? In fact, only once over many seasons, did I recover a Barnes X bullet that was not 100-percent intact – and, that was because one petal of the mushroom head had broken off. In the vast majority of cases, however, these bullets plow through, and subsequently, are not recoverable. I have used Barnes copper bullets for deer in several calibers and the results are always the same; their advertising and photos are genuine.

As for the common Hornady Black or Custom factory ammunition, it is as accurate as anything out there. In fact, I’ve taken a number of whitetails with the Hornady Flex Tip ammo and all fell with single shots. However, the more explosive nature of the bullet’s construction causes the jacket to separate from the core of the bullet at moderate to close range.

This can never happen with the Barnes X bullets, because there is no jacket; they represent the epitome of controlled expansion and penetration.

If all goes according to plan at the range, Barnes Vor-TX will get the nod for the first time this season in the big bore. Otherwise, plan B with the Federal Fusion load is not bad at all.