The Genius of the Modular AR 15

By Raul Mas

The Modern Sporting Rifle (MSR), most of which are based on the AR-15 design, has become the most popular long gun in America today. A recent report <https://www.nssf.org/articles/commonly-owned-nssf-announces-over-24-million-msrs-in-circulation/?hilite=MSRS> from the National Shooting Sports Foundation (NSSF) suggests that almost 25 million of these firearms have been produced or imported into the United States since 1990.

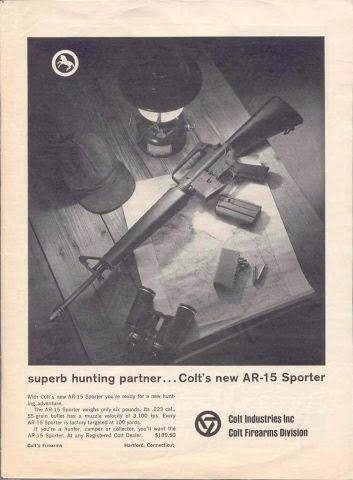

Despite media efforts to brand them as “assault rifles” and “weapons of war”, most gun owners know that the MSR is simply today’s version of semi-automatic rifle technology dating back to the turn of the 20th century and Remington’s introduction of the Autoloading Repeating Rifle. First introduced in 1906, the gun was later renamed the Model 8 <https://www.americanrifleman.org/content/the-remington-model-8-a-look-back/> in 1911 and it became a commercial success; despite stiff competition from popular lever action designs that had “won the West” and the Winchester Model 54 bolt action rifle introduced in 1924. Semi-autos became increasingly popular after World War II as surplus M-1 Garand rifles and M-1 carbines began making their way onto target ranges and hunting fields. By 1964, the Colt AR-15 rifle also made its commercial debut:

While the internet is full of AR-15 videos and information, a lot of it is missing the detailed knowledge necessary to properly inspect, measure, gauge and assemble your parts into a safe and reliable rifle. By safe and reliable, I mean one that is chambered and headspaced correctly, where the gas system is neither overgassed or undergassed, where the parts are torqued to the correct specifications using the proper tools and torque values, and with the appropriate lubricants or sealants. In addition, the rifle must feed factory ammo correctly with G.I. issued M4 magazines or quality commercial magazines. Finally, the receiver extension components should produce reliable cycling, including the appropriately timed extraction and ejection of the spent cartridge cases.

Learning all that requires superior instruction. You can’t get it by watching You Tube videos from unknown “experts” with no verifiable credentials…or by a self-taught ninja/operator with a bad case of acne.

In my opinion, the undisputed fountain of AR-15 knowledge is found today at the School of the American Rifle (SOTAR) <https://schooloftheamericanrifle.com/> run by Chad Albrecht. That is not to say there aren’t other good instructors out there. However, after taking his two-day course in mid-August, I seriously doubt that you will find a more knowledgeable individual on the proper assembly, operation, and maintenance of a direct impingement AR-15.

Chad’s instruction is highly personalized and very much hands-on. There were five students in my class. Chad has trained only about 600 individuals face-to-face since launching SOTAR several years ago. He is dedicated to quality instruction and considers himself a perennial student of the AR platform. Chad had just returned from taking the Colt M-16/AR-15 Armorer’s Course before the start of our weekend class in eastern Maryland. He shared with us that he had learned several things he didn’t know before, and he spoke highly of Dean Caputo, the legendary armorer and instructor who has been teaching AR-15 and 1911 pistol courses almost as long as I can remember.

There is a lot to be said for a subject matter expert who doesn’t pretend to be one, and who is constantly seeking out more knowledge and better ways of doing things. That is Chad Albrecht.

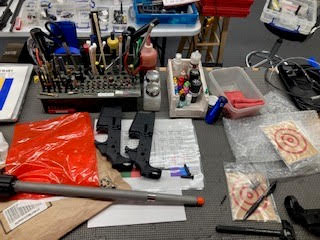

Class began at 8 AM Saturday morning and ran to about 8 PM on both days. The only breaks were bathroom breaks and a lunch break to eat some delicious, hot pizza delivered daily. The day began with a thorough summary of the AR-15’s method of operation and an in-depth discussion of how to diagnose– and fix— the most common problems one is likely to encounter. We learned how to use the equipment that Chad has come to depend on after years of testing practically every tool and fixture available in the marketplace. Likewise, he provided detailed information on the correct specifications for practically every part, pin, hole, screw, spring, angled surface, weight, depth, length, and thread pitch and diameter associated with the AR-15. Maintenance, cleaning, and lubrication were covered in-depth. Lesson number one: don’t be obsessed with cleanliness, but lube is essential.

In addition, Chad emphasized more than just the assembly and disassembly procedures taught to an armorer. He also taught us some basic gunsmithing techniques– including filing and polishing– to fix out-of-spec parts and ensure they will fit well and “play well” with other parts.

Day One was like drinking out of a fire hose. After a couple of hours, I simply couldn’t write fast enough to keep up with the quantity of information being presented. You also couldn’t keep writing because you found yourself turning wrenches, gauging, or inspecting parts under his careful watch…or watching him teach a fellow student how to fit, fix or replace something. There was heavy emphasis on the fire control group and installing triggers, safety selectors, plus bolt and magazine catches properly. Receiver extensions, springs and buffers were also discussed.

On Day Two, the pressure of the fire hose increased. It was time to rebuild the rifles we had brought, or in my case, to build a new precision AR-15 using an 18” White Oak Armament SPR barrel and other components. We took a very deep dive into the bolt carrier group, the heart of the AR-15, as well as the gas system parts and how they all needed to fit properly. Pin gauges were used to measure gas port diameters. Chamber and head space gauges were used to ensure that nothing would blow up next to our faces. We learned how to use a bore scope and utilize it to ensure a perfect fit with a gas block. We learned how to check for correct firing pin protrusion (.028 to .036) and how to make sure there was proper tension on the extractor and the ejector. All our assembled rifles were then carefully inspected by Chad and test-fired in an indoor Savage bullet trap. Ejection patterns were noted, and recoil springs and buffer weights were adjusted to ensure that fired cases ejected between 3 and 4 o’clock.

Chad’s course was everything I expected…and then some. I thought I knew the AR-15 well before taking this course. Little did I know how little I really knew. It was an eye-opener and absolutely worth the tuition, airfare, car rental, and motel accommodations to travel from Miami, Florida, to Elton, Maryland.

If you have the time and resources to take Chad’s course in-person you won’t regret it. If you can’t, Chad is developing some cutting-edge online resources that, once completed, will likely become the gold standard for web-based instruction on the AR-15 platform.

If you’re interested in attending a course, the link to the School of the American Rifle (SOTAR) can be found here <https://schooloftheamericanrifle.com/course-description/> SOTAR maintains a very useful blog page on their website and Chad’s You Tube videos <https://www.youtube.com/channel/UCaUOYvlDrZh5LWILrVDUM4w> are a great resource and give you a good idea of his teaching ability. Check them out.