“Shotgun Report Technoid” Bruce Buck Answers Questions

Whigham, GA – At Trulock Choke Tubes, we know our customers have many questions on patterning with differing shot sizes, shot column length and load size, do buffered loads help and more, which is why an article by the Shotgun Report Technoid, Bruce Buck titled, “Bunch of Questions,” hit the proverbial nail on customer questions. We reached out to Bruce and received permission to reprint the article to share. It was originally posted on the Shotgun Report on September 14, 2021.

Dear Technoid,

Perhaps this frisky little question is worthy of the Volcano of Knowledge? Actually, a couple of questions:

1) Will smaller size shot, say #8 or 7-1/2, deform more or less than #4 shot, in example, affecting patterning adversely?

2) Will a 1 oz. lead charge deform more in a smaller gauge, 16 or 20, due to the longer “stack height” of the pellets?

3) Is height of the pellet stack a minus re: 3? and 3-1/2? magnum loads?

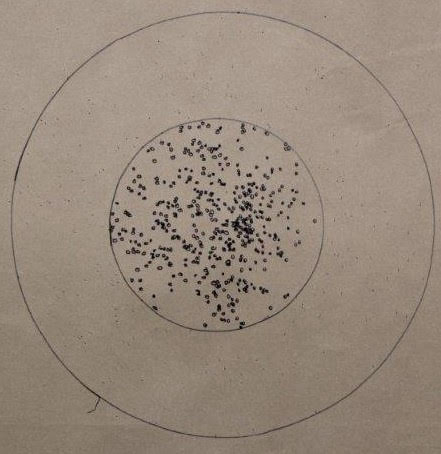

4) Has the Technoid found any evidence that buffered loads do any good?

5) The Omnipotent Technoid has stated that copper-plated shot seems to slide its way through game, proving less effective than lead. Does the copper do much re: reduction in pellet deformation?

6) And finally (are you glad!), can the Technoid speculate as to the rise and fall of the popularity of the 16 gauge? Just picked up an A-5 Sweet Sixteen, and really enjoy popping clays with it.

7) Oops, one more – can the Technoid recall approximate shot cloud sizes at forty yards for 1 oz. launched through 12, 16, and 20 ga., assuming “modified” choke performance?

Thanks Bruce, for all your help!

Randy

Dear Randy,

Wow! I could make a living off of your questions

(that is, if Shotgun Report ever provided a living – send money and we will see). Answers to questions one through five are “YES.” Ta dah! Ok, Vanna, let’s show our guest what he has won.

1) I don’t really know if small shot deforms more easily than big shot or whether deformation affects the small shot more than the large shot due to its smaller mass, but the result is the same. Bottom line is that shot hardness is not as important as the pellet grows in size.

Traditionally, when the shot makers make their “Magnum” (high antimony) offerings they put their highest antimonial contents in the #8 and #7 1/2 sizes. #9s and #6 get a bit less and then it falls off rapidly. In the BB sizes, the difference between “magnum” and “chilled” shot can be only 2 percent vs 1 percent. My point is that they would not be able to get away with doing this if larger shot didn’t inherently resist deformation (or its effects) better than small shot. Maybe you engineers out there who really know what you are talking about can give me the mechanical why-fors. I am just a practical user who flunked Algebra Two.

2) and 3) These are really both the same “shot column length” questions. The longer the shot column (the height of the stack of shot when it is in the shell awaiting launch time), the more the pellets at the rear get squashed at lift off. The more squashed pellets there are, the more that they fly out of the pattern. It is that simple. The total shot payload really isn’t the question. It is a matter of shot column height.

Example: put one ounce of shot in a ten-gauge shell. (I am cribbing from the Alliant Reloader’s Guide here- they have done all the work already). Due to the width of the 10 gauge bore, the shot column is only .610? high. This means that the shot “passengers” riding at the rear (bottom) of the launch vehicle only get squashed by a .610? inch high column of lead.

Now look at the miserable skinny idiot stick .410 bore. One ounce of shot jammed in there is almost like putting it down a McDonald’s soda straw. The shot column would be a monstrous 2.175? long for that same one ounce. This means that at ignition, the pellets in the back would have 3 1/2 times as much weight on top of them and would thus suffer MUCH more damage and deformation. In fact, this is exactly what happens and is one of the reasons why it is so hard to get the .410 to pattern well.

The bore size/ shot column length is also one of the reasons why the manufacturers are touting “backboring” (actually, factory enlarged bores) as a pattern enhancer. They may be right in theory, but the difference between the old .729? and the new .740? is so slight that it is really just marketing hype.

4) Yes, buffered loads help lead shot. Brister’s book covers a lot of that. The buffered concept has fallen out of favor because it was really only worth buffering large lead shot loads, the type used in waterfowl. Now that non-toxic is required and lead is out for waterfowl, there is no point in buffering, except maybe for buck shot. Buffering for steel is not necessary as steel does not deform at ignition.

5) I have never really liked copper coated pellets on game because I do think that they “grease” through birds and don’t shock them as much on impact. Copper is popular with many people because manufacturers usually only bother to plate their hardest shot, so when you buy copper coated shot, you know that you are getting the hardest shot that the manufacturer can make. At least that is the theory. That was why the old Lubaloy shot was so popular. Not so much for the copper coating, but for the hardness.

Copper and nickel coatings do provide the shot with a lubricity that helps is slide around within the shot column as it goes down the barrel and into the choke. This ability to slide a bit helps plated shot avoid some deformation that lead gets when it sort of sticks together as it gets jammed into the forcing cone and bore. This is the main reason that plated shot patterns a bit better than unplated shot. There may be some advantage to plated shot also in having less aerodynamic friction, but I can’t prove that. I have seen some awful shiny fresh pure lead pellets. Of course, the plated shot doesn’t oxidize as badly or as quickly either.

6) As to the 16 gauge, it remains popular in Europe, as it always has been. Here it has been virtually supplanted by the 3? 20 gauge and the light 12. There is nothing wrong with the 16, but it is a hassle getting shells. Life is much simpler with the very slightly ballistically inferior 20.

7) That question is really a lot more complicated than it looks and I am going to save it for another time.

Best regards,

Bruce Buck

Shotgun Report’s Technoid

(Often in error, never in doubt.)

About Trulock™ Choke Tubes

George Trulock began manufacturing chokes in 1981 to solve the dilemma of creating a choke system that could be retrofitted into most shotgun barrels without the use of an adaptor or machine tools. His final design launched The Tru-Choke style choke tube in 1982. Since then, this proprietary system has been adopted by several shotgun manufacturers as O.E.M. and copied by a number of aftermarket choke makers. Trulock™ chokes now stocks approximately 2,000 different choke part numbers and has come a long way from George’s first piece of production equipment, a Warner and Swasey # 2 turret lathe.

Trulock™ Chokes has grown from a one-man show to a company that employs 30 people producing products 24 hours a day, 5 days per week. Trulock™ Chokes is still a family-owned business with George’s sons, Scott and Jerrod, a vital part of the management team.

Trulock™ Chokes has three goals: to make the best product, to give the best customer service and to have 100 percent customer satisfaction. In the event a customer is not completely satisfied with their purchase, they can return it for a refund or exchange within 60 days from the date of purchase. Watch videos and get questions answered on what type of choke to buy at https://www.youtube.com/user/TrulockChokes. Buy Trulock™ Chokes online at TrulockChokes.Com.