Trulock: Guide to Patterning with Choke Tubes for Waterfowlers

Whigham, GA – In order to see the results of a quality pattern when patterning a shotgun, there are two equally-important elements needed that the experts at TrulockÔ Choke Tubes have found. One is a high-quality choke tube, like those sold at Trulock, and the other is a high-quality shotshell. Picking a lesser quality choke tube or a lesser quality shotshell will give poor results. When choosing choke tubes, choose TrulockÔ Choke Tubes with no frills, no gimmicks and no hype, just solid guaranteed performance or your money back.

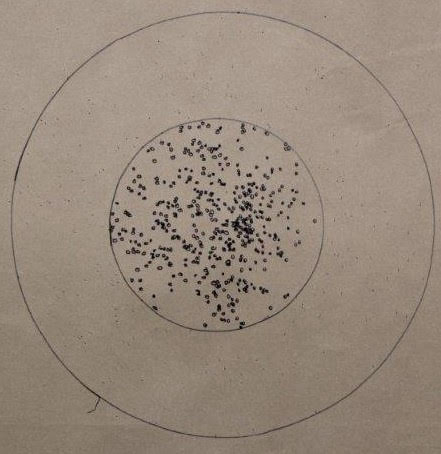

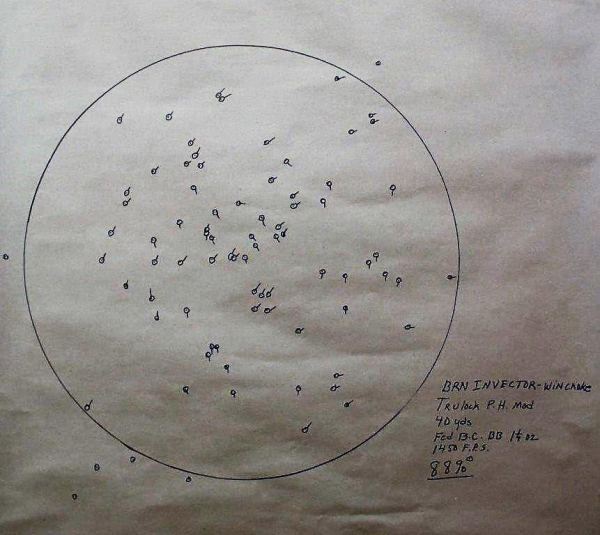

Here is an example for waterfowl hunters. The photo below shows a Trulock 12-ga Precision Hunter Modified, Winchoke, Browning Inv., Mossberg 500 series with a Federal Black Cloud shotshell giving an 88 percent pattern density at 40 yards. See more details about this pattern here.

Trulock designs, builds, and tests all their choke tubes at their facility in Whigham, Georgia, using state-of-the-art CNC manufacturing. That process has allowed them to develop these chokes with special exit diameters that produce dense, hard-hitting patterns in all 12-gauge loads suitable for waterfowl hunting.

Trulock’s engineers are waterfowl hunters themselves, and that’s why these chokes tubes have several features to make them practical and versatile in the field under a wide range of conditions.

Like all TrulockÔ Choke Tubes, the same experts involved in the initial design are present through all phases of product development, testing and manufacturing. That means waterfowl choke tubes have been extensively tested, both on paper and in the field — TrulockÔ Choke Tubes don’t go out the door until Trulock can guarantee they consistently produce superior performance in pattern density and uniformity.

In fact, Trulock offers the best guarantee in the business: your money back if you’re not satisfied, and a lifetime guarantee against failure as long as you own the choke.

To learn more about choke tubes, shotgun patterning, and how to get the best choke for your hunting needs, check out Trulock’s home page at https://trulockchokes.com

About Trulock™ Choke Tubes

George Trulock began manufacturing chokes in 1981 to solve the dilemma of creating a choke system that could be retrofitted into most shotgun barrels without the use of an adaptor or machine tools. His final design launched The Tru-Choke style choke tube in 1982. Since then, this proprietary system has been adopted by several shotgun manufacturers as O.E.M. and copied by a number of aftermarket choke makers. Trulock™ chokes now stocks approximately 2,000 different choke part numbers and has come a long way from George’s first piece of production equipment, a Warner and Swasey # 2 turret lathe.

Trulock™ Chokes has grown from a one-man show to a company that employs 30 people producing products 24 hours a day, 5 days per week. Trulock™ Chokes is still a family-owned business with George’s sons, Scott and Jerrod, a vital part of the management team.

Trulock™ Chokes has three goals: to make the best product, to give the best customer service and to have 100 percent customer satisfaction. In the event a customer is not completely satisfied with their purchase, they can return it for a refund or exchange within 60 days from the date of purchase. Watch videos and get questions answered on what type of choke to buy at https://www.youtube.com/user/TrulockChokes. Buy Trulock™ Chokes online at TrulockChokes.Com.